Textiles are softshell fabric factory made impermeable to fluids by two processes, coating and laminating. Lamination consists of bonding pre-prepared polymer film or membrane with one or more textile substrates using adhesives, heat, or pressure. Coating is the process of applying a viscous liquid fluid or formulated compound on a textile substrate. .In this paper we have gone through several methods of production used to manufacture a wide range of coated or laminated fabrics.

Broadly, they are knife coating, lick roll coating, transfer, rotary, Zimmer, melt coating, and flame lamination & hot melt lamination. A review is made on Coated and laminated textiles applications in Defence, transportation, healthcare, space, environmental pollution control, sports, architecture, and many other diverse end-product uses.There are two definitions of a 'coated fabric'. The first one is, 'A material composed of two or more layers, at least one of which is a substantially continuous polymeric layer and at least one of which is a textile fabric. The layers are bonded closely together by means of an added adhesive or by the adhesive properties'.

The second definition is, 'A textile fabric on which there has been formed in situ, on one or both surfaces, a layer or layers of adherent coating material.Ever walked on a carpet? Lay on a new mattress? Maybe you’ve watered your garden with a hose pipe at one point? Gone camping? Worn gloves?Carpets, mattresses, hose pipes, tents and gloves of today are often treated with either laminations or coatings. This improves their durability, and can often render them waterproof, dirtproof, etc.Yep, you’ve come into contact with a remarkable process known as textile composite development.Because coating and laminating are used to apply properties to textiles that are not present when the textile is in its ‘natural’ state, we call this a process of composite creation.

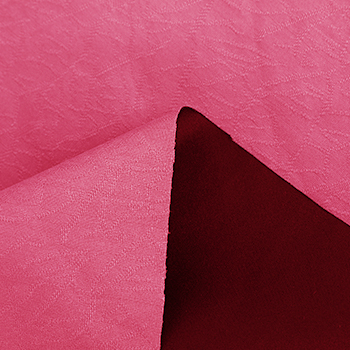

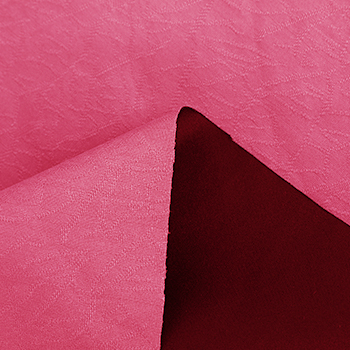

This is because the end result is a composition of a textile and non-textile components.The fundamental differences between coating and laminating fabrics is in the method of application. A fabric coating is applied in liquid form, penetrating the fabric structure and filling air pockets.As mentioned above, the lamination of textiles differs to textile coatings in the method of application. The laminate is a pre-set covering that is applied in solid form and rests on the fibres, leaving air pockets under the laminate surface.Coated and laminated fabrics are used so extensively today, if it were to stop, we’d barely recognise many of the items we use every day! Below are a few laminated and coated fabric applications from a few industries.